Maximizing Efficiency in Plastic Injection Molding Machine Operations

Plastic injection molding provides several valuable opportunities for companies to receive quality components and products to increase customer satisfaction. Additionally, using lean manufacturing principles in the injection molding process can reduce cycle time and lead times while focusing on continuous improvement so everyone involved has a better experience.

For Plastic Injection Molding Quotes

Plastic Injection Molding: Quality and Efficiency in Manufacturing

Two of the biggest issues for any company that’s moving goods through its doors and out to the consumer are quality and efficiency. A severe problem in either one of those areas can mean considerable difficulties and unhappy customers. However, plastic injection moulding can be a game changer. Understanding what the injection molding industry can do for you is the best place to start.

No More Excess Inventory Storage Issues

Whether you’re keeping finished goods or raw materials, having too much on hand can be frustrating and costly. There aren’t always good places to store large quantities, and your production line may not be able to keep up. That affects sustainability and can even mean products expire or become unusable.

Meet Customer Demand More Efficiently

When you work with injection molding companies, you can avoid any overproduction and stop yourself from getting into the cycle of having either too much or not enough inventory based on fluctuating order fulfillment.

Fill Customer Requirements With Ease and Confidence

When you have the right support, there’s no need to say no to a large customer order or worry about how your company will meet its obligations. You can also avoid significant downtime by working with a company that can provide the plastic parts you need when you need them most.

Lead Times and Cycle Time Can Make or Break End-User Deals

When your customers need your products, you want to get them where they need to be quickly. If you can’t, you could lose out to a competitor with a better timeline. Through a lean manufacturing process, though, a company specializing in plastic injection molding in Illinois can get you what you need so you can provide high value for your customers.

Get Your Finished Products Out Faster and More Efficiently

No matter what kinds of plastic injection parts you need to keep your production line moving, knowing where and how to get them can make all the difference. Your customers are not concerned about whether you created all the parts for the goods you are selling as long as those goods meet their needs and timelines.

Create a Value Stream That Meets Company and Customer Needs

The right value stream gives your company what it’s looking for and also provides that same experience to your customers. By having an on-demand level of support for the parts you need to fulfill your orders, you avoid overproduction or underproduction issues that can affect inventory space and customer satisfaction.

Rework Your Product Flow for Increased Value

A strong product flow is vital whether you send goods onto store shelves or into the hands of specific customers who order directly from you. If your current product flow is inefficient, plastic injection molding can be the answer you are looking for.

Plastic Injection Molding: A Comprehensive Approach to Production

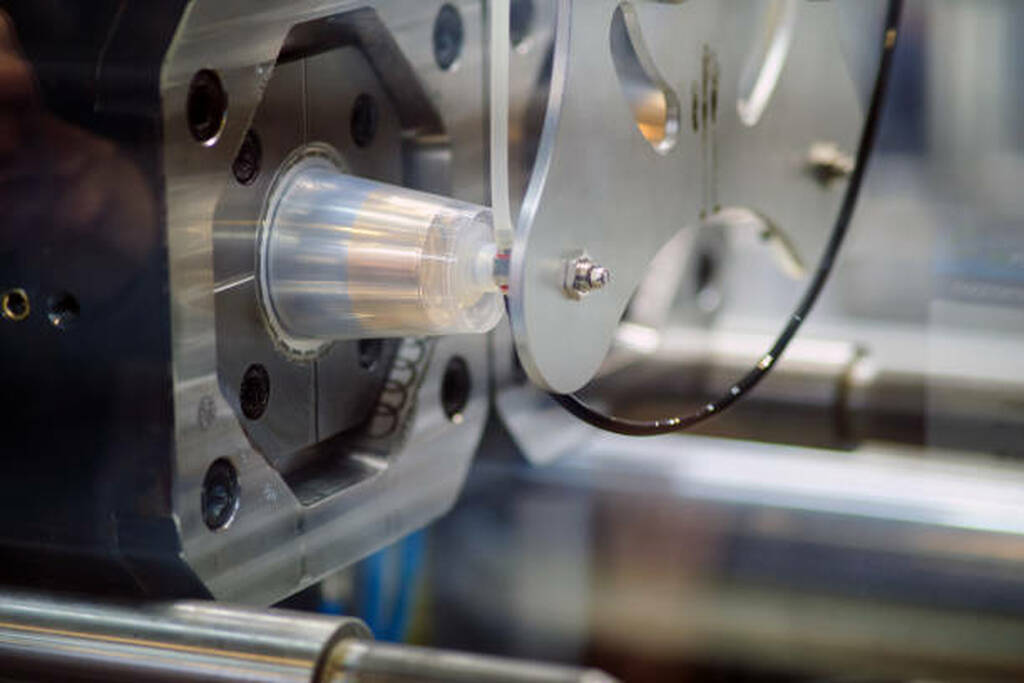

Your company needs a comprehensive, detailed production process devoid of unneeded downtime and other problematic issues. That’s where injection molding machines come in. They can provide the specific parts you need, down to the dimensions you and your customers require.

Maximize Your Production Time Expectations

Production time is one of the most significant issues where goods are concerned, especially if your customers are working on a tight deadline. With that in mind, you want to ensure your production efforts are being used fully. Injection moulding offers that opportunity.

Shorten Wait Times for Increased Value

Wait times are another big issue for many companies because they can’t provide what customers need if they don’t have the required parts. Fortunately, custom injection molding gives your company a trusted partner who can have what you need ready for you on your timeline. Not only does that mean a smoother production experience, but it also keeps customers happier.

Lower Scrap Rates With Quality Options

The quality you get from working with a trusted plastic injection molding company means your product scrap rate is lower. That’s true for individual parts and also for the finished products, so more of what you create can reach customers. This lowers your overall costs and encourages additional efficiency.

Plastic Injection Molding: Waste Reduction and Enhanced Efficiency

A plastic injection molding machine is the best way to create the proper size, shape, density, and type of parts you need for your company’s products. The correct plastic parts allow your company to provide value for customers and offer them a quality experience that is efficient, trustworthy, and sustainable. A molding injection machine can meet your company’s goals for reducing waste while keeping efficiency high.

Hit Your Metrics With Just-in-Time Availability

Just-in-time availability is a vital part of many production lines. When you have metrics to hit, you do not have the time or space for excess product storage or downtime due to a lack of parts. Receiving your plastic molded parts right on time is the way to keep your company’s production schedule on track and make meeting customer demands easier.

Avoid Overprocessing and Increase Process Improvement

Depending on your company’s type and size, as well as the equipment and worker skill levels, process improvement may be a serious consideration. Alternatively, you may not have the space or ability to create or sustain some of the processes you need to keep your company advancing. The plastic injection molding process can increase your options.

Feel Confident in Your Manufacturing System Support

Not only do you need an excellent and reliable manufacturing system, but you also need quality support from trusted outsiders who can enhance the value you provide. You can enjoy peace of mind, confidence, and a successful production and manufacturing experience by utilizing your plastic injection molding machine options.

The Benefits of Lean Manufacturing from Trusted Injection Molders

Are you ready to optimize your manufacturing process and boost efficiency? Contact us at CBM Plastics today for a free consultation. We’ll show you how lean manufacturing practices can revolutionize your operations and take your product quality and production cycle times to the next level. Discover more about the revolutionizing custom plastic injection molding techniques shaping the future of manufacturing. Our value added production system can take your product quality and production cycle times to the next level.

Contact CBM Plastics USA for your plastic injection molding quote.

Let us help you with a custom injection molding quote for your project.

FAQs For Plastic Injection Molding

If your company requires plastic components made to exact specifications on a timeline and schedule that works for you and your customers, injection molding will likely add ongoing benefits to your company and enhance its bottom line.

Production time varies depending on the specifics of your order. However, with the right machinery and equipment, you can expect fast production times and good communication that will keep you informed about when you can expect your order.

CBM Plastics provides the highest product quality and takes plastic injection molding seriously. This allows you to have confidence in your order and ensures your customers will receive products with lasting components.

A plastic injection molding machine provides high precision and consistency in creating parts, helping to reduce scrap rates and improve product quality. This leads to lower costs and enhanced customer satisfaction by meeting exact specifications and timelines.

Waste reduction is crucial in plastic injection molding as it leads to cost savings and environmental sustainability. A molding injection machine ensures precise production, which minimizes material waste and enhances overall efficiency.

For More Frequently Asked Questions About Custom Plastic Injection Molding Check Out This Comprehensive Resource.