Industries Using Plastic Injection Molding for Growth and Innovation

For a long time, plastic injection molding companies have been a cornerstone of modern manufacturing and the creation of consumer products. It enables the mass production of precise, durable, and cost-effective components across numerous types of markets. From medical devices and consumer electronics to automotive and construction, this process is driving the future of product development and industrial competitiveness.

Here’s what to know about the top plastic injection molding industries in 2025 in the USA, the advantages this process brings to each, and how this versatile process continues to fuel innovation.

Automotive Industry: Driving Efficiency and Lightweight Design

The automotive sector remains one of the largest injection molding industries in the United States. It relies heavily on precision-molded components from injection molded plastic to meet evolving demands for safety, fuel efficiency, and sustainability.

For plastic injection molding, automotive parts include dashboards, bumpers, grilles, door panels, and under-hood components that are all designed to be lighter than traditional metal alternatives without sacrificing strength or performance.

Key innovations include reducing vehicle weight and improving fuel efficiency, as well as supporting electric vehicle (EV) range optimization. Additionally, high-performance polymers can now withstand extreme temperatures and chemical exposure, and overmolding combines multiple materials or inserts into one part, improving assembly efficiency and durability.

For Plastic Injection Molding Quotes

Medical Industry: Precision and Biocompatibility at Scale

The medical field depends on medical devices injection molding applications that deliver consistency and hygiene, as well as regulatory compliance. From medical equipment for diagnostics to implantable components, use of an injection molding machine enables precise mass production of sterile, high-quality parts such as syringes, IV connectors, surgical handles, diagnostic test kits and housings, and implantable and single-use components through both mold design and manufacturing methods.

Medical-grade mold tooling requires cleanroom environments, biocompatible resins, and meticulous quality assurance throughout the entire manufacturing process. Manufacturers must comply with FDA, ISO 13485, and other stringent standards to ensure patient safety.

Consumer Goods & Packaging: Cost-Efficient and Sustainable Production

From toothbrushes and kitchen tools to reusable containers and toys, plastic injection molding enables efficient, large-scale production for everyday items. The process supports a variety of textures, finishes, and materials, making it easier for manufacturers to balance durability and appearance with affordability in a wide range of plastic parts.

Recent trends in the plastic products market include biodegradable and recycled plastics that reduce environmental impact, along with ergonomic shapes and aesthetic finishes to add market appeal. Additionally, the use of high-speed automation reduces cost per part and accelerates delivery times.

Consumer Electronics: Compact, Durable, and Sleek Designs

In the competitive world of consumer electronics, injection molding allows manufacturers to create thin, durable housings and intricate internal parts for devices like smartphones, earbuds, laptops, and smart home systems. These plastic parts must have tight tolerances, heat resistance, and customization options. With growing demand for wearable tech, IoT devices, and lightweight components, the injection molding process helps electronics manufacturers push the boundaries of design and functionality.

Construction and Infrastructure: Strength Meets Innovation

Plastic injection molding plays a vital role in modern construction, as it helps to supply durable, lightweight, corrosion-resistant components that outperform traditional metal or wood alternatives. For an in-depth look at how molded plastics are reshaping the built environment, see The Use of Plastic Injection Molded Parts in Modern Construction.

Common applications of these plastic materials include pipe fittings, fasteners, brackets, electrical junction boxes, insulation panels, modular wall systems, and decorative trims. These parts resist moisture, chemicals, and UV damage, and offer long-lasting reliability for indoor and outdoor use.

Industrial and Agricultural Equipment: Rugged Performance Under Pressure

In industrial machinery and agricultural applications, injection-molded parts provide toughness, dimensional stability, versatility, and resistance to abrasion and chemicals for components like equipment housings and protective covers, Valves, couplings, and seals, and control handles and grips.

Custom injection molding enables consistent performance under high stress and exposure to harsh environments, and its advanced polymer blends allow manufacturers to replace metal components to reduce equipment weight and prevent corrosion.

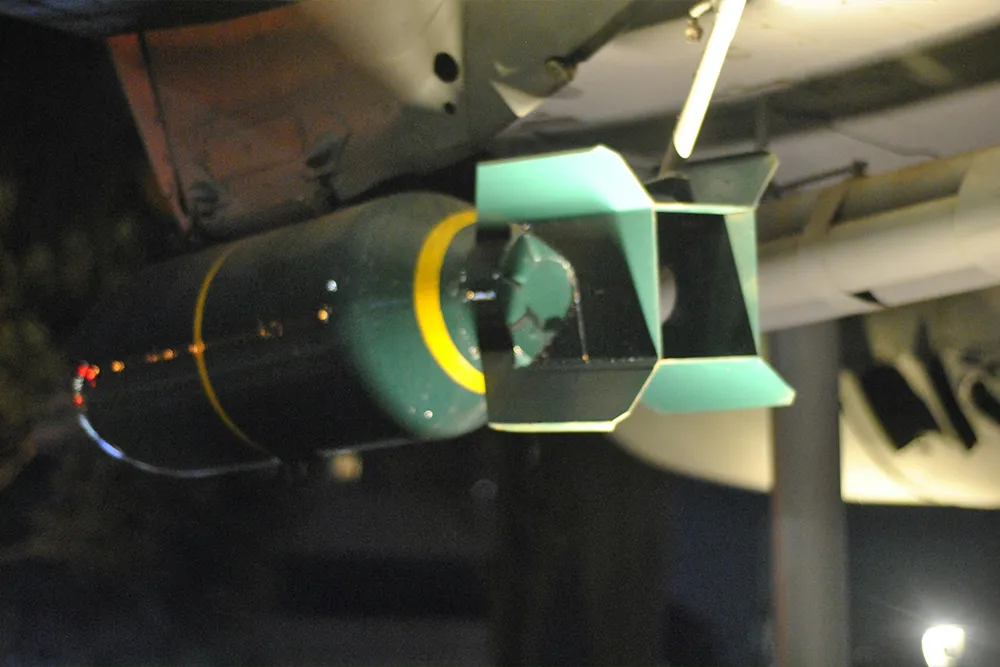

Aerospace and Defense: High-Performance Polymers for Safety and Precision

The aerospace and defense industries rely on high-performance polymers and thermoplastics that can endure extreme conditions while maintaining low weight and dimensional accuracy. Injection-molded aerospace components include air ducting, cable assemblies, and fasteners, interior panels and enclosures, and electronic housings and sensor mounts.

These parts are required to meet strict FAA and MIL-SPEC standards, and injection molded products support that precision with tight tolerances, repeatability, and traceability throughout the production cycle. Advanced materials also provide exceptional strength-to-weight ratios, flame resistance, and thermal stability.

As additive manufacturing and lightweight composite technologies evolve, the benefits of injection molding continue to enhance and complement these processes. That offers cost-effective scalability and high-volume consistency for a growing and vital industry.

Regional Strengths and Industry Growth in Illinois

The Midwest is a powerful hub for American manufacturing, with states like Illinois leading the charge in materials innovation, tooling expertise, and end-to-end production. Our article on Illinois Plastic Injection Molding: Regional Capabilities & Use Cases highlights how this region’s strong supply chain, skilled workforce, and advanced manufacturing infrastructure make it a strategic location for OEMs seeking domestic production partnerships.

Illinois molders also serve diverse markets, from automotive and medical to electronics and agriculture, and offer both low- and high-volume production backed by decades of engineering excellence.

As reshoring trends accelerate, regional manufacturers are becoming critical partners in strengthening the U.S. injection molding industry’s competitive edge for 2025 and beyond.

Emerging Sectors: Renewable Energy, Robotics, and Smart Tech

Looking to the future, injection molding industries are rapidly expanding into new territories driven by sustainability, automation, and advanced materials science. Growth areas include:

- Renewable energy: Molded components for solar panels, wind turbines, and energy storage systems.

- Robotics: Lightweight housings and mechanical components for automated systems.

- Smart infrastructure: Connected devices that rely on miniaturized, durable plastic housings.

These emerging applications showcase injection molding’s adaptability, as well as how molding can offer scalability, material diversity, and precision unmatched by other mass-production processes.

Industry Evolution Requires Innovative Options

From automotive and medical to construction and electronics, the industries using custom plastic injection molding services continue to grow and develop through advanced design capabilities. As technology and materials improve, manufacturers across numerous industries are unlocking new possibilities for performance, safety, and efficiency.

Whether your business is producing plastic injection molding automotive parts for EVs or advancing medical devices injection molding applications for next-generation healthcare, the future of manufacturing is tied to precision, creativity, and collaboration.

Contact CBM Plastics USA for your plastic injection molding quote.

Let us help you with a custom injection molding quote for your project.

FAQs For Plastic Injection Molding

If your company requires plastic components made to exact specifications on a timeline and schedule that works for you and your customers, injection molding will likely add ongoing benefits to your company and enhance its bottom line.

Production time varies depending on the specifics of your order. However, with the right machinery and equipment, you can expect fast production times and good communication that will keep you informed about when you can expect your order.

CBM Plastics provides the highest product quality and takes plastic injection molding seriously. This allows you to have confidence in your order and ensures your customers will receive products with lasting components.

A plastic injection molding machine provides high precision and consistency in creating parts, helping to reduce scrap rates and improve product quality. This leads to lower costs and enhanced customer satisfaction by meeting exact specifications and timelines.

Waste reduction is crucial in plastic injection molding as it leads to cost savings and environmental sustainability. A molding injection machine ensures precise production, which minimizes material waste and enhances overall efficiency.

For More Frequently Asked Questions About Custom Plastic Injection Molding Check Out This Comprehensive Resource.