Plastic Injection Molding, Illinois

CBM Plastics USA

We are dedicated to providing outstanding custom plastic injection molding services in Illinois. With our state-of-the-art facilities and experienced team, we specialize in delivering exceptional quality and precision for all your plastic component needs. Whether you require high-volume production or intricate designs, our commitment to excellent craftsmanship and customer satisfaction sets us apart as a trusted partner in the industry.

Let our team at CBM Plastics USA create a cost-effective solution without compromising quality, tailored to your needs. Our efficient and reliable injection molding services provide cutting-edge technology for precision and consistency. We pride ourselves on exceptional customer service and are experienced in serving various industries.

For Plastic Injection Molding Quotes, Illinois

Why are we your ideal choice for custom injection molding quotes in Illinois?

CBM Plastics USA offers reliable and efficient injection molding services in Illinois. With cutting-edge technology and a skilled team, we deliver high-quality and cost-effective solutions across various industries. Our customized approach, exceptional customer service, and commitment to precision set us apart as a trusted partner for all your injection molding needs.

We also offer other services such as thermoforming and profile extrusion to complement our injection molding services.

Injection Molding Quote, Illinois – The CBM Plastics USA difference

Efficient and Reliable Plastic Injection Molding

When it comes to injection molding, we understand the importance of efficiency and reliability. Our streamlined process ensures quick turnaround times without compromising on quality. From the initial concept to final production, we optimize every step to deliver results that exceed expectations.

Experienced in Serving Various Industries with Plastic Injection Molding

CBM Plastics USA boasts a well-established history of catering to a diverse range of industries. With extensive expertise spanning across automotive, aerospace, electronics, medical, and consumer goods sectors, we are adept at addressing your specific needs. Whether you seek precision components for electronic devices or robust parts for Injection Molding Agriculture, our team is thoroughly experienced in delivering customized manufacturing solutions that align perfectly with your unique industry demands. Trust us to meet and exceed your expectations, no matter the complexity of the project or the industry you represent.

Cutting-Edge Technology for Precision and Consistency

To maintain the highest standards of quality, we leverage cutting-edge technology and advanced equipment. Our state-of-the-art facilities ensure precise molding, consistent results, and adherence to strict industry standards. By utilizing the latest technologies, we can achieve exceptional accuracy and minimize any potential defects or inconsistencies, ensuring that your injection molded products meet rigorous specifications.

Cost-Effective Solutions without Compromising Quality

At CBM Plastics USA, we prioritize cost efficiency for businesses and collaborate closely with our clients to optimize designs and manufacturing processes. This approach ensures the delivery of cost-effective solutions without any compromise on the final product’s quality. Our commitment is to offer exceptional value for your investment by providing competitive pricing while upholding the highest standards of craftsmanship.

Customized Solutions Tailored to Your Needs

We highly appreciate the distinctiveness of every project, driving us to provide personalized injection molding solutions tailored precisely to your specific requirements. Our dedicated team of expert engineers and designers collaborates closely with you at every step, ensuring your vision is meticulously brought to life. Your satisfaction is our ultimate goal, and we are fully committed to turning your ideas into tangible reality.

Throughout the process, we pay meticulous attention to detail, from careful material selection to comprehensive design optimization. Our aim is to deliver outstanding outcomes that not only meet but exceed your expectations. Your project’s success remains our utmost priority, and we strive to achieve the highest levels of customer satisfaction.

Exceptional Customer Service in Custom Injection Molding

At CBM Plastics USA, we prioritize exceptional customer service. We believe that strong relationships are built on open communication and trust. Our team is dedicated to providing personalized attention, responsive support, and proactive solutions to ensure a seamless experience from start to finish.

Custom Injection Molding Quote at CBM Plastics Illinois, USA

CBM Plastics USA employs a streamlined process to assist customers in their injection molding needs. Our process involves several stages from initial consultation to final production, ensuring a smooth and efficient experience.

Consultation on your custom injection molding quote needs

Our team engages in a comprehensive discussion with clients to understand their specific requirements, design preferences, and project goals. This allows us to gather essential information needed for the subsequent stages.

Design and Engineering of your custom injection molding quote

Using the gathered information, our experienced engineers and designers work closely with clients to develop customized designs and engineering solutions. We utilize advanced software and tools to create accurate 3D models and prototypes for client approval.

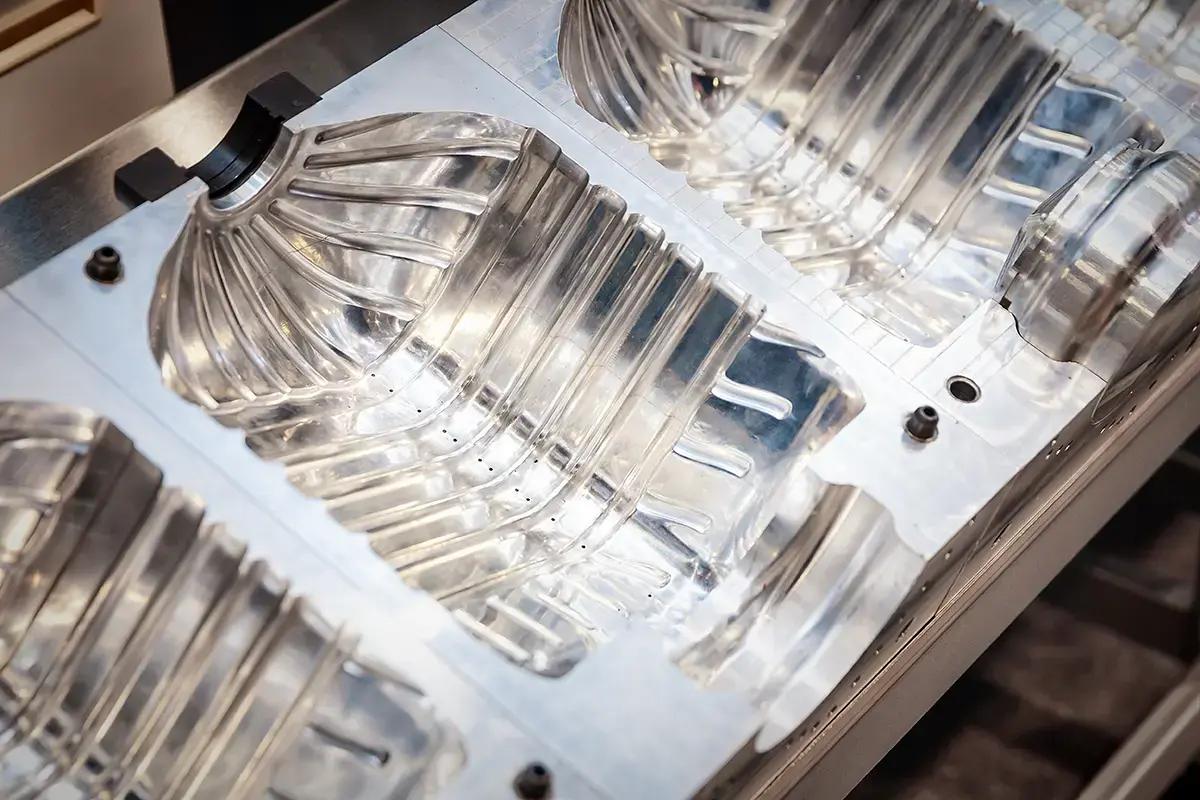

Tooling and Mold Manufacturing of your custom injection molding quote

At CBM Plastics USA, after finalizing the design, our skilled technicians use state-of-the-art machinery to meticulously manufacture high-quality molds with precision and attention to detail. We ensure the molds meet strict quality control measures, resulting in reliable and durable products that cater to various industries unique requirements.

Injection Molding Production

With the molds ready, we initiate the injection molding production process. Our manufacturing facilities are equipped with advanced injection molding machines capable of handling various materials, sizes, and complexities. Stringent quality control measures are implemented to maintain consistent and impeccable results throughout the production run.

Quality Assurance of your custom injection molding quote

We prioritize quality at every step of the process. Our in-house team conducts rigorous inspections to ensure that the finished products meet strict industry standards and client specifications. We perform thorough testing and validation to guarantee the durability, functionality, and overall performance of the injection molded parts.

Timely Delivery of Injection Molding

CBM Plastics USA located in the midwest near Chicago understands the importance of timely delivery. We work diligently to meet agreed-upon timelines and strive to exceed client expectations in terms of turnaround times without compromising on quality.

Ongoing Support

Our commitment to customer satisfaction extends beyond the completion of the project. We provide ongoing support and assistance to address any post-production queries, concerns, or additional requirements our clients may have.

Overall, CBM Plastics USA’s process is designed to provide a seamless and efficient experience for customers, ensuring exceptional quality, customization, and support from start to finish.

Benefits of Plastic Injection Molding

Plastic injection molding offers numerous benefits, making it a preferred manufacturing method for a wide range of industries. Some key advantages of plastic injection molding include:

- Versatility

- Cost-Effective

- Efficiency and Speed

- Material Selection

- Consistency and Consistent Quality

- Strength and Durability

- Waste Reduction

- Design Flexibility

These benefits collectively make plastic injection molding an ideal choice for the production of high-quality, cost-effective, and versatile plastic components for various industries and applications.

What is Plastic Injection Molding?

Plastic injection molding serves as a versatile manufacturing process for creating a wide array of plastic parts and components. The method involves injecting molten plastic material into a mold cavity, where it cools and solidifies to acquire the desired shape.

To achieve this, an injection molding machine comes into play, featuring a hopper that feeds plastic pellets into a heated barrel. A screw or plunger system then pushes the plastic through, causing it to melt under the combination of heat and pressure.

Once the plastic material reaches the perfect molten state, it is forcefully injected into a mold cavity with high pressure. The mold cavity is designed in the shape of the intended part and consists of two halves: the core and the cavity. These halves create the negative space that defines the final part’s shape and features.

After injection into the mold cavity, the plastic is left to cool and solidify within the mold. This cooling phase allows the material to harden and retain the mold’s shape. Once adequately cooled, the mold opens, and the solidified part is ejected.

Plastic injection molding offers numerous advantages, including the ability to produce complex and intricate parts, high production speed, and cost-effectiveness for large volumes.

Custom Plastic Injection Molding Quote Illinois | CBM Plastics USA

Injection Molding FAQs

What is injection molding?

Injection molding is an industrially utilized manufacturing process designed for producing plastic parts in large quantities. This efficient method entails injecting molten plastic material into a mold cavity with substantial pressure. The material then cools and solidifies within the mold, taking on the desired shape for the final product.

What types of products can be made with injection molding?

The versatility of injection molding empowers the manufacturing of an extensive array of products, ranging from tiny and intricate items like gears and buttons to larger components like agricultural or Injection Molding Auto and household appliances.

How do you design a mold for injection molding?

Designing a mold involves considerations like part design, material selection, gate and runner design, cooling system design, and ejection methods. Proper mold design is crucial for producing high-quality parts efficiently.

What is the typical lead time for an injection molding project?

Lead times are subject to variation based on the intricacy of the part, mold availability, and production volume. Straightforward projects may be completed within a few weeks, whereas more intricate ones might extend the timeline to several months.

What are the benefits of injection molding?

Injection molding offers several advantages, including high production efficiency, repeatability, intricate part design capabilities, low labor costs, and minimal material waste.

What is the injection molding process like?

Typically, the injection molding process involves a series of sequential steps: material feeding and melting, injection of the molten material into the mold, followed by cooling and solidification. Subsequently, the mold opens, and the finished part is ejected to complete the cycle.

What materials can be used in injection molding?

Common materials employed are ABS, polystyrene, polypropylene, polyethylene, PVC, and nylon. These versatile options offer diverse properties, making them suitable for a wide array of applications in the manufacturing process.

Contact CBM Plastics USA for your injection molding quote, Illinois.

Let us help you with a custom injection molding quote for your project.